Marvon S.r.l. was founded in 1967 and has gone through 50 years of industrial history, interpreting the requirements of an ever-evolving economy.

On the domestic market, it has achieved brilliant results in the molding industry and the processing of plastic materials looking also to international markets at a time when internationalization was an adventure for few Italian companies.

An important milestone marked this long road: the launch of the safety product line for the passive fire protection market.

The production of firestop doors handles and intumescent seals, accessories for doors producers, has opened new possibilities in the field of passive compartmentalization in the building sector, where intumescent materials are required, as well as for passive protection of modular joints for continuous facades, or as filling materials for firestop collars or for the insulation of fire resistant cable ducts.

In 2002 Marvon has become a member of the Silmar Group, an industrial reality at the top of the Italian entrepreneurial sector.

Company

Marvon, within its 3 different departments ensures an extremely precise and functional service, sustained both by technologically advanced machinery and by a high level of pre and post sales assistance.

The quality of the galvanic processing is recognised on an international level in the European industrial landscape.

The high tech molding department guarantees reliability and allows Marvon to maintain high levels of appreciation on the market.

Through the extrusion line of business, Marvon today is recognised as a dynamic company, rich in stimulating experiences, thanks to the number and quality of the articles produced in 35 years of presence on the market.

Silmar Group

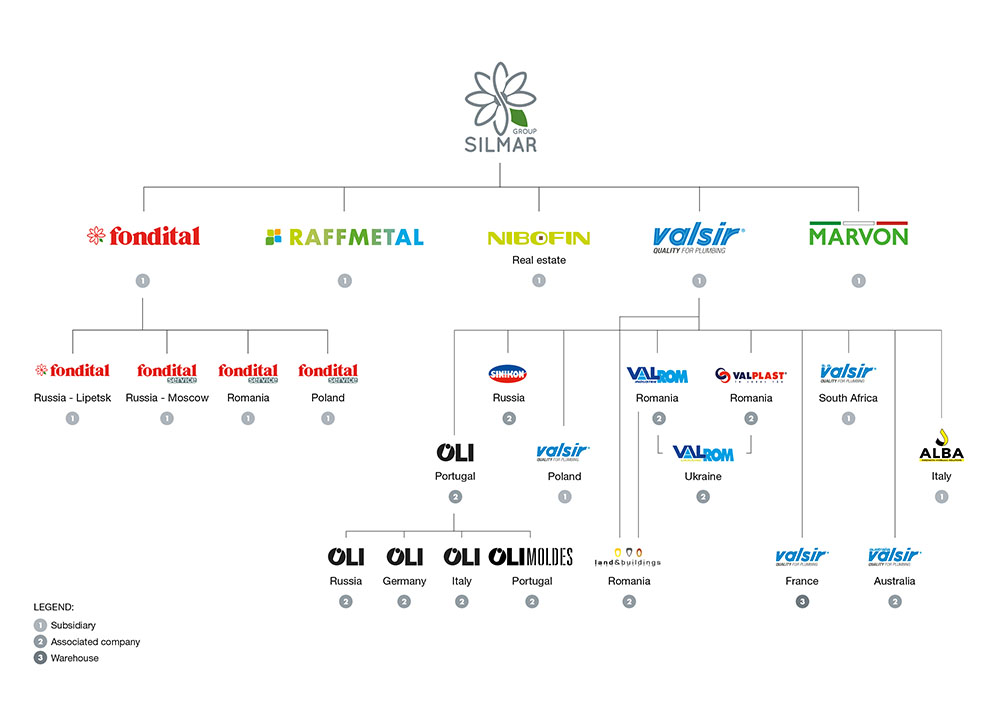

Silmar Group originates in 1970 and its production ranges over 5 different industries: heating, aluminium processing, plumbing, electroplating and passive fire protection. It all began with the foundation of Fondital, a manufacturer of aluminium radiators that today operates on the market with two brands: Fondital and Nova Florida.

To be independent in the procurement of quality raw materials, while developing the area of aluminium recovery and recycling, Raffmetal was integrated into the group. Following this, Valsir was founded, a leading company in the supply of products for the plumbing and heating industry and finally Marvon was integrated, a leading company in the electroplating industry and in the production of passive fire protection devices.

The group operates on an international level with Oli in Portugal and in Italy, Moldaveiro molds in Portugal, Sinikon in Russia, Valrom and Valplast in Rumania, Valrom Ucraina in Ukraine, Valsir Polska in Poland and the logistics centres Valsir Uneeq in South Africa and Valsir France.

This activity of internationalization is not done with the purpose of relocating but with the aim of encouraging the sale of products in local markets. Our group philosophy is not in fact to produce in countries with cheap labour in order to import into Italy and keep production costs down, but rather to create companies, jobs and prosperity in the countries where we are present, serving local markets.

OUR HISTORY

THE 60s

Marvon is founded, a small business dealing with the extrusion of PVC pipes for the irrigation market.

THE 70s

The company activates new processes: injection molding and electroplating of plastic materials. The first plastic accessories appear on the furnishing market: caps for metal pipes and feet for shelves and armchairs.

THE 80s

The launch of the production of components for cups and trophies: Marvon is the first company in Europe to produce these items in plastic that are electroplated with chrome and gold finishes.

THE 90s

With the introduction of new technologies and the need to diversify production, Marvon looks toward the household market.

THE 2000s

2000

A new division is created dedicated to the passive prevention of fire and including intumescent graphite-based seals, and handles for fire doors

2002

In the month of September Marvon joins the Fondital Group.

2006

Marvon penetrates the Russian market, quickly becoming market leader.

2007

The 40th anniversary of its foundation is celebrated with the obtainment of the ISO 14001 environmental certificate.

2008

The business strategy of the company approaches an unexplored sector:luxury packaging. positioning itself amongst the most important companies in the industry.

2009

The range of intumescent seals is doubled: Marvon is in its own right a reference point in Italy and international markets for passive fire protection.

2010

The range of inox handles for fire doors is launched on the market.

2012

The quality management system is certified by the Swedish certification body DNV according to ISO 9001.

2013

Daisy, the fire-stop sleeve is patented and launched:Daisy, an innovative and high performing product with exceptional technical properties.

2014

An innovative handle with spring is launched on the market which further extends the range of handles for fire doors. .

2015

Investments in production continue and the fleet of machines is expanded reaching 19 production units and integrating 2 new presses weighing 1200 tons and 1500 tons.

EOTA (European Organisation for Technical Approvals) accepts the request for obtainment of the CE mark on the intumescent seals.

2016

Extension of the passive fire protection range with the introduction of: Tecno-F 240, polyurethane foam resistant up to 240 minutes and Tecno-S 240 acrylic sealant resistant up to 240 minutes

2018

The energy management system is certified by the Swedish certification body DNV according to ISO 50001.

2019

Extension of the passive fire protection range with the introduction of: Tecnoboard, fire board composed of mineral wool

2020

Extension of passive fire protection range with the introduction of: Tecnowrap, Tecnobag, Tecnobrick e Tecnographit

MARVON IN THE WORLD

Through our network of distributors we reach over 30 countries around the world, supplying a range of over 3000 products.

World presence awards the continuous commitment of Marvon in the pursuit of high quality standards and technically innovative products.

An extended range of products and continuous technological research together with efficient and rapid logistics allows us to operate and intervene rapidly, no matter where, to guarantee the full satisfaction of our customers that is and remains our main objective.

GREEN SOUL

In March 2007, Marvon reached the important goal of environmental certification according to UNI EN ISO 14001 which is periodically renewed

Much attention is given to the impact that production activities have on the environment.

Marvon is periodically subjected to stringent tests by authorized institutions and has obtained authorization to discharge the water used in galvanization directly into the river. This was made possible thanks to an important investment in a powerful and technological purifier, a cutting-edge facility in water treatment.

The motivation behind the implementation of an environmental management system was the desire to sustainably combine environmental protection and the production requirements of a growing company, with the awareness that the commitment of each one of use is a fundamental condition to maintain and increase our position in the market, but above all to improve the quality of life of present and future generations.

SUSTAINABILITY

Today efficient processes and reliable products are not enough to assess the quality of a company behaviour. Of equal importance are the capacity of a company and its management to design and implement sustainable processes.

SUSTAINABILITY REPORT

The gathering of data and facts concerning our everyday commitment finds now place in the sustainability report, born from the will of establishing a more open dialogue with those getting in touch with us, communicating what has been already done as well as the goals set for the future.