Daisy

DAISY is Marvon’s fire collar designed and developed to ensure El 240 fire resistance of penetration seals on wall and floor according to EN 1366-3.

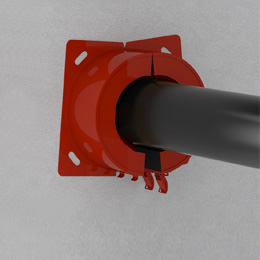

DAISY is made of a red coated steel shell that can be opened to allow the accommodation even on already installed pipes and it has a hanger with a latch mechanism. The back flange with attachment buttonholes ensures a simple setting and a fast installation. The resistance and insulation El 240 is guaranteed by the presence of two different types of intumescent graphite based reactive material (TECNOFLAME + EVA) and of special closure metal elements (petals).

The ethylene vinyl acetate (EVA) seal expands fast at low temperatures whereas the seal TECNOFLAME expands later so that it ensures high performance in time. While expanding, the intumescent seals act on the closure elements (petals) bringing them towards the position of fire exposure, creating an additional barrier.

Application field

The fire collar DAISY can be used on rigid wall (masonry, concrete or aerated concrete) and on rigid floor (concrete or aerated concrete).

It has an EI 240 fire resistance classified according to EN 13501-2 for:

- Combustible pipes (PVC-U, PVC-C, PE, LDPE, MDPE, HDPE, ABS, SAN+PVC, PP)

- Combustible soundproof pipes (e.g. Valsir Triplus®, Valsir Silere®, Valsir PP3, Valsir Blackfire®)

Technical data

|

Fire resistance |

EI 240 |

|

Fire reaction |

NPD |

|

Diameters |

Ø 32 - 160 |

|

Collar’s height |

49,5 - 89,5 mm |

|

Shell |

Carbon-coated steel (1 mm thickness) with a lever hook and slotted flange |

|

Intumescent material |

Two different types of intumescent seal:

|

|

Colou |

Red |

|

Storage |

Unlimited (in normal conditions) |

Operating principle

In the event of fire, the intumescent material contained in the collar expands forming a “plug” thus cutting off the fire and preventing the passage of gas and fumes.

The special closure elements (reinforcement wings) increase the reactivity and efficiency of the system by completely squeezing the plastic pipe during the melting phase.

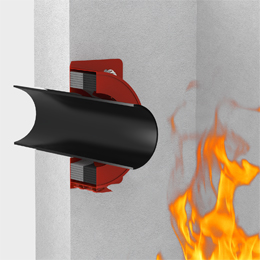

Phase 1

In the first phase of the fire, the plastic pipe melts and the intumescent elements expand. The first, more reactive, acts immediately, the second, which expands at a higher temperature, gives higher performance over time.

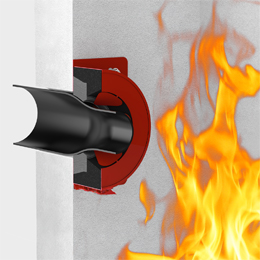

Phase 2

In the minutes that follow, the intumescent elements occupy the entire section that is left free after the plastic pipe has melted. The intumescent elements act on the closure elements (reinforcement wings) bringing them toward the position of exposure to the fire.

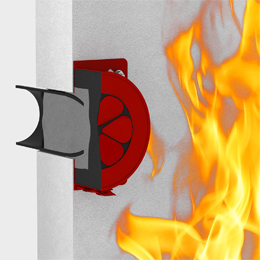

Phase 3

The intumescent elements close off the hole entirely in a sufficiently brief time so that the fire does not spread outside the compartmentalization. The closure elements (reinforcement wings) in this phase are completely oriented and, as well as acting as a “container” for the expanded intumescent material, create another metal barrier against the fire.

Installation phases

Make a hole in the wall or ceiling and insert the pipe.

Prepare the sealing mortar required to completely fill the space between the pipe and the hole.

Seal the gap with the sealing mortar

Position the collar against the wall or ceiling and trace the position of the holes.

Drill the holes for the wall plugs.

Mount the Daisy collar onto the pipe and secure it using the lever closure.

Insert the plugs in the holes.

Tighten the nuts.

The Daisy collar has been installed.

Standard rules and certifications

- Test Standard: EN 1366-3

- Fire Classification Standard: EN 13501-2

-

Classification Reports:

- CSI1862FR – wall

- CSI1915FR - floor

- CSI1917FR - wall