TECNO-S 240

TECNO-S 240 is Marvon’s a single-component acrylic sealant designed and developed to ensure the fire resistance up to El 240 of penetration and linear joint seals on wall and floor according to EN 1366-3 and EN1366-4.

Application field

TECNO-S 240 can be used on flexible wall (plasterboard), rigid wall (masonry, concrete and aerated concrete) and on rigid floor (concrete or aerated concrete).

It has a fire resistance up to El 240 classified according to EN 13501-2 for:

- Combustible pipes (PVC-U, PVC-C, PE, LDPE, MDPE, HDPE, ABS, SAN+PVC, PP)

- Combustible soundproof pipes (e.g. Valsir Triplus®, Valsir Silere®, Valsir PP3, Valsir Blackfire®)

- Insulated and non-insulated multilayer pipes

- Insulated and non-insulated incombustible pipes (copper or steel)aio)

- Single or bundled electrical cables

- Single or bundled electrical cables

- Empty holes

- Linear joint and gap seals

Technical data

|

Fire resistance |

Up to El 240 |

|

Fire reaction |

D-s1, d1 |

|

Characteristics |

Single-component acrylic sealant |

|

Weight |

550 g/pcs |

|

Expansion in fire |

1:2 / 3 |

|

Application temperature |

5 - 30°C |

|

Colour |

White |

|

Airborne sound insulation |

Rw (C; Ctr) = 62 (-1; 5) dB |

|

Content, emission and/or release of dangerous substances |

IA1, S/W3 |

|

Storage |

18 months (in normal conditions) |

|

Working life |

30 years |

|

Durability |

Z2: use for internal conditions (relative humidity between 50% - 85% and |

|

AVCP system |

1 |

Standard rules and certifications

- Test Standard: EN 1366-3 – EN 1366-4

- Fire Classification Standard: EN 13501-2

- European Assessment Document: EAD 350454-00-1104 – ETAG 026-3

- European Technical Assessment: ETA 16/0993 – ETA 16/0994

POIGNÉES POUR PORTES COUPE-FEU

La fonction fondamentale d'une poignée de sécurité pour portes coupe-feu consiste à garantir l'ouverture de la porte durant et après un éventuel incendie. Les équipes de secours doivent en effet pouvoir ouvrir à tout moment les portes séparant les zones à risque.

Il est donc fondamental que la fonctionnalité et la résistance soient garanties aussi bien pour la porte que pour les composants accessoires.

Les normes en vigueur à ce sujet prévoient elles aussi des dispositions de plus en plus strictes pour assurer la sécurité.

(Journal Officiel n° 271 du 18.11.2004).

Pour ces raisons, la construction de la poignée est réalisée selon les critères de qualité et de sécurité les plus scrupuleux.

Avantages

- Testée pour fonctionner pendant plus de 200 000 cycles d'ouverture

- Poignée en résine autoextinguible

- Poignée an acier inox

- Âme en acier avec caractéristiques anti-feu

- Parfaite compatibilité avec les nombreuses serrures et barres antipanique disponibles sur le marché

- Possibilité de fournir des poignées colorées

- Possibilité de fournir des poignées fluorescentes pour faciliter l'identification des issues de secours

- Certifiée conformément à la norme DIN 18273 FS

Caractéristiques de construction

- Acier DC-02 pour l’âme métallique, l'amortisseur et la plaque

- Acier S235JR pour le carré creux de 9 millimètres

- Acier pour les vis de fixation (cylindre RST 36 DIN 17311 + vis 4,8 zinguée blanche)

- Polypropylènes chargés pour la matière plastique (PP noir 30% ca Co3)

Qualité

Le Kit poignée MARVON a été certifié conformément à la norme DIN 18273 (obligatoire pour le marché allemand) à l’Institut MPA de Dortmund.

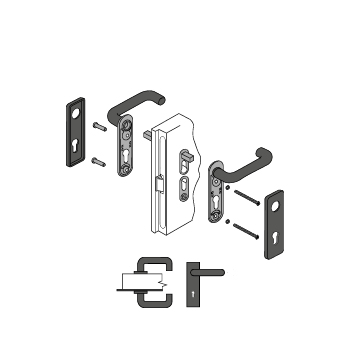

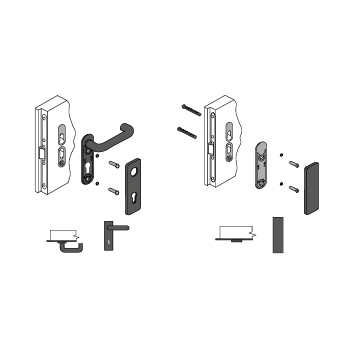

UTILISATIONS PRÉVUES

Les kits poignée sont indiqués pour une installation sur des portes dotées d'une serrure à enfiler avec un entraxe de 72 mm et un carré de 9 mm.

Les kits de fourniture sont composés selon la liste indiquée sur notre catalogue.

Kits personnalisables en cas d'exigences particulières et de normes en vigueur dans d'autres pays.

Application sur des portes à passage normal sans caractéristiques coupe-feu ni anti-fumée :

Ce kit poignée à utiliser sur des portes aux fonctions non réglementées a pour but de garantir des performances de sécurité, fonctionnalité et durabilité environnementale dans le temps. Le tout sans renoncer au design.

Utilisation sur des portes destinées aux sorties de secours :

Ce kit poignée à utiliser sur des portes destinées aux sorties de secours a pour but de fournir une ouverture simple et immédiate en une seule manœuvre en mesure de libérer le dispositif d'urgence.

Application sur des portes de compartimentage coupe-feu ou anti-fumée :

Garantir un fonctionnement durable en contribuant à la résistance des portes à l'action des flammes et de la chaleur provoquées par un éventuel incendie.

DÉFINITIONS ET TYPOLOGIE

Poignée avec ressort

Poignée avec ressort qui en garantit

le retour dans l'axe

Poignée standard

Poignée sans fonction d'urgence avec actionnement des deux côtés.

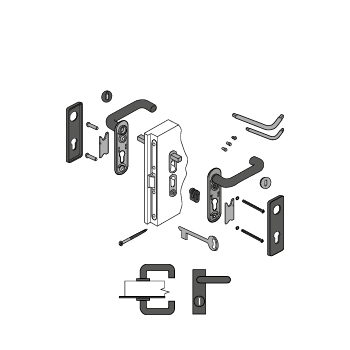

Poignée avec dispositif d'urgence

Poignée avec fonction d'urgence pour sorties de secours (serrure spéciale). Actionnement des deux côtés.

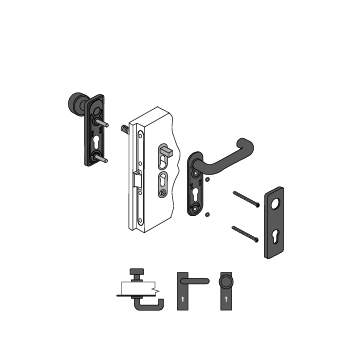

Poignée alternée

La poignée ne se trouve que d'un seul côté de la porte ; l'autre côté est doté d'une manette fixe. Il est possible de modifier et d'équiper le dispositif pour la fonction d'urgence.

Poignée pour vantail semi-fixe avec plaque aveugle

À installer sur des vantaux semi-fixes de portes

à deux vantaux.

Demi-poignée

En position fixe et tournante, elle est fixée sur une seule face de la porte.

CERTIFICATIONS

Marvon a testé et certifié ses poignées en partenariat avec des clients excellents auprès de laboratoires autorisés, distribués dans différents pays européens.

Les produits Marvon ont été soumis à des essais mécaniques et thermiques rigoureux auprès du laboratoire interne et auprès des organismes de certification afin de garantir une qualité élevée et constante.

Passive fire protection

Products

Fire prevention

The main purpose of fire prevention is to prevent fires from starting and then to stop them from spreading and finally to stop reaction by rapid quenching methods.

Fire protection is ideally divided into active and passive fire protection.

ACTIVE AND PASSIVE PROTECTION

Active protection measures aim at reducing the frequency and intensity of fire through early detection and suppression when the fire is still in its initial phase.

Passive protection measures, the heart of Marvon production, aim at:

- Limiting damages to structures

- Avoiding or limiting the harmful effects of the productions of combustion.

Some of our installations:

Montebelluna Medicine Center

Treviso, Italy

Kauno Arena

Kaunas, Lithuania

Travel Charme Hotel

Salò, Italy

Apple Store

Milan, Italy

Dolce&Gabbana Boutique

Paris, France

Green Plaza by Grivalia

Athens, Greece

Cà Foscari University

Venice, Italiy

Hotel Monopol

Katowice, Poland

Intumescent seals

Marvon intumescent seals are an essential complementary accessory for the construction of high performing fire doors.

In order to obtain a certificate of approval a fire door must possess certain characteristics that provide a complete barrier to fire and smoke for a variable period of time in relation to the requested approval. (30, 60, 90, 120 minutes).

The European standard for fire doors is being prepared under a mandate from the European Commission. As the European standard is as yet incomplete, CE marking for fire performance is not possible. Each member state of the EU therefore refers to national standards, which are updated periodically with the European standards that have been completed. To date, therefore, there are different criteria for importing fire doors in a country and it is essential that functionality and resistance be guaranteed both for the door and for the components of the same.

The seals have the fundamental characteristic of expanding significantly in volume when exposed to elevated temperatures or flames. They must therefore be incombustible or flame-retardant.

They must also combine good mechanical resistance with their heat resistance performance. This means guaranteeing easy positioning on the frames with normal temperatures of use and room temperatures and, at the same time, remain securely in place during the expansion phase of the same, due to the effect of the heat or the fire at high temperatures.

In other words, the seals must remain in place once they have expanded in order to seal off the rooms, withstanding the mechanical stress resulting from the fire. The seals may therefore be called on to resist forces of positive and negative pressure produced by the fire even of a significant entity. In the event of inadequate mechanical resistance, the seals could allow the fire and smoke to pass through the cracks and gaps thus allowing the fire to spread.

Advantages

- Wide range of sizes with high application possibilities

- Available with and without double-sided adhesive

- Possibility of co-extruding a coloured pigmentation that with equal intumescence improves appearance

- Totally insensitivity to moisture and weatherproof for easy storage

- Possibility of supplying in standard 100 meter coils or in personalized lengths on request

- High expansion ratio – up to 10 times the initial thickness

- Expansion pressure equal to 5 bar

- Absence of organic solvents

- Product approval according to Deutsches Institut für Bautechnik: Zulassungsnummer z-19.11.1533

Intumescence

Marvon intumescent seals at 450°C form, with a load, a stable, slightly elastic and porous foam.

Expansion pressure and intumescence start to develop at a temperature of about 180°.

At 180°, the material is in its greatest state of relaxation.

Above this temperature, the material starts once more to harden resulting in a material that is substantially harder than the original material.

Marvon seals are made of a combination of different top-quality materials:

- PVC resin

- Plasticisers

- Flame-retardant and intumescent graphite

- Loads that delay the spread of fire with characteristics that control the smoke

- Ecological heat stabilizers

- Excipient resin to improve the bond between the various components

Characteristics

- Ratio between the initial volume when cold and that of maximum expansion: 1:10

- Average expansion pressure: 5 Bar

- Totally water resistant and weatherproof

- Absence of organic solvents

- Flame retardant

For particular applications, Marvon has developed and patented a technology for the production of composite seals with high mechanical and thermal resistance: Tecnoflame intumescent seals, which consist of a high-resistance fibre support net included in the thermoplastic material.

Tecnoflame

Co-extruded

Tecnoflame

Tecnoflame Wood

Tecnoflame

hot/cold smoke

The particular formulas of the Marvon products

can be used in a multitude of production processes:

Flexible and rigid seals with rectangular profile

They can be applied to fire doors in metal, wood or a composite material, for example, between the frame and leaf; fire shutters, membrane ceilings, (perimeter seals) etc…

Flexible seals with shaped profile

Passageways, expansion joints, joints of fixed modular panels etc…

Production of molded items

Handle plates (fire stop handles), lock plates, pipe sleeves, passageways, boxes etc…

Co-extruded seals with two colours

Fire doors in wood, steel and/or composite materials. All the seals can be provided with a double-sided adhesive tape on one side; application of the tape on the seal is performed automatically and directly during the production phase of the same. The seal with double-sided adhesive tape can be applied easily and quickly. The seals without double-sided adhesive tape are on the other hand applied by the client using mechanical fixing tools or glues.

CERTIFICATIONS

Marvon has tested and certified its seals in collaboration with excellent clients in authorized laboratories, located in different European countries.

Marvon products have undergone severe mechanical and thermal testing in its own laboratory to guarantee high and on-going quality over time.

In relation to the intumescent seals, the Italian standard does not indicate specific certificates. The abovementioned certifications therefore relate to complex products, that is, to the combination of Marvon intumescent seals with fire doors, certified and approved by manufacturers of the fire doors.

Fire prevention

The main purpose of fire prevention is to prevent fires from starting and then to stop them from spreading and finally to stop reaction by rapid quenching methods.

Fire protection is ideally divided into active and passive fire protection.

Active protection measures aim at reducing the frequency and intensity of fire through early detection and suppression when the fire is still in its initial phase.

Passive protection measures, the heart of Marvon production, aim at:

- Limiting damages to structures

- Avoiding or limiting the harmful effects of the productions of combustion.

This is achieved through compartmentalization, ventilation systems, emergency evacuation plans and other measures.

Therefore, both the structural elements and those used for completion not only perform an essential function but also a second function of no less importance, adhering to the regulations in the field of fire prevention.

The structural elements are: foundations, load-bearing walls, beams, slabs, roofs, etc…

Completion items are on the other hand: cladding materials, walls, windows, etc.

The characteristics of all the elements, for the purposes of the fire prevention provisions, are expressed in terms of performance determined by regulation and standardized technical procedures.

Such performance fundamentally regards two aspects: the reaction to fire of the materials and the fire resistance of the products.

The reaction of materials to fire regards the participation of a material with the fire to which it is exposed. It essentially expresses the ability of a material to feed and propagate a fire, depending on its physical and chemical characteristics.

If a material is fireproof, that is, not likely to burn, it is clear that the degree of participation with the fire will be inexistent. If it is flammable, that is, likely to burn, therefore to allow the fire to ignite and develop, its degree of participation in the fire will be positive.

In view of the difficulty in defining a real fire, from its outbreak to the complete development of the same, the degree of participation of a material in the fire, that is its reaction to fire, is assessed on the basis of empirical evidence that refers to a conventional fire model. In Italy, such tests are performed in accordance with the procedures and classification criteria established in the Ministerial Decree of 26 June 1984.

The decree identifies six classes of reaction to fire, varying from 0, for incombustible materials, to 5 for combustible materials in relation to their greater susceptibility to trigger, propagate and maintain combustion.

Unlike reaction to fire, resistance to fire expresses a characteristic that does not relate to the materials but to a building component, regardless of the materials used.

Such a characteristic is identified in the capacity of the component to preserve, in the event of fire, the functions for which it was designed, created and installed.

Depending on the functions, fire resistance ratings are designated by certain criteria:

Fire stability(R)

The ability for a building element to maintain its mechanical resistance when exposed to fire.

Fire resistance integrity(E)

The ability of a construction element, when exposed to fire on one side, to prevent the passage though it of flames and hot gases and to prevent the occurrence of flames on the unexposed side.

Insulation(I)

The ability of a construction element to restrict the transmission of heat within specified levels.

Fire resistance is normally expressed with the symbols R, RE, REI followed by the time limit during which the elements retain the requirements indicated by the terms.

The time, expressed in minutes, is determined based on the presumed potential of the fire by means of the estimation of the so-called fire load and the definition of the building class.